It’s not top thickness, that’s only 3 layers and the bulge is on more layers than that.

Printed with PLA, 4 perimeters, 15% gyroid, but no infill makes difference, i don’t think this is about shell thickness.

Retraction is good, there is no oozing on retract moves and no stringing on the printed parts.

Otherwise the prints come out okay so i’m a bit stuck with this one!

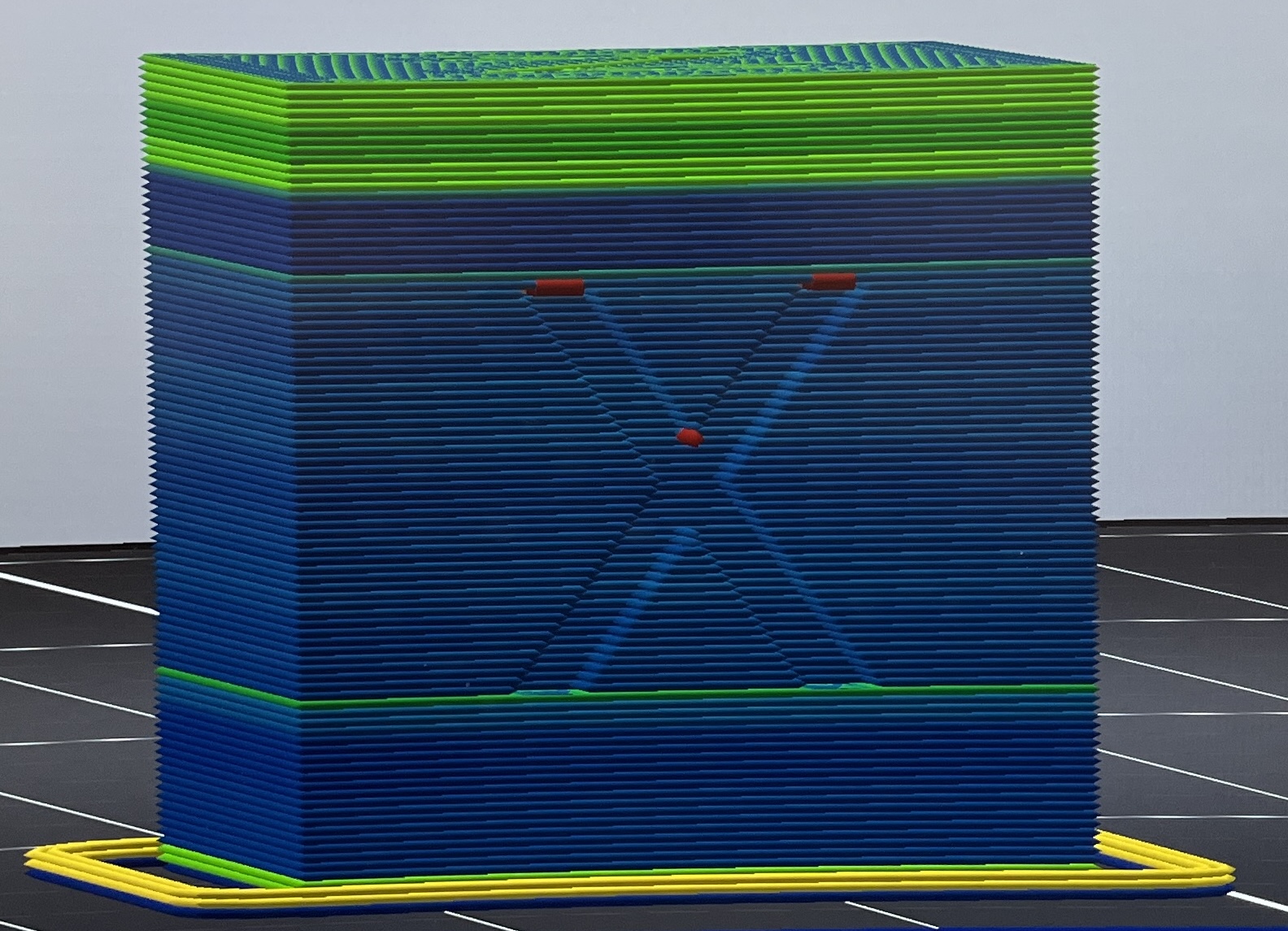

You can see the bulging in all three edges on the picture, about 3-4mm from top to bottom, then a few ok layers, then again a few layers with bulges on corners.

Slicer is Prusa if that’s relevant.

Any ideas are welcome!

That’s weird. Is there anything set in the slicer at that height? Some fade settings, speed changes, anything?

Damn, i would’ve never thought about that. Went to check the speed in prusa, would you look at that…

Perfectly corresponds to the bulges.

Thank you, Detective Carighan!

That’s interesting tbh, especially given the one line in the middle. I usually use Cura, so I’m unfamiliar with the Prusa Slicer, what setting causes that variable speed?

But it’s fascinating, I can even see the bulge in the layer of the single line in your photo, now that I know what to look for. That’d also tell me that maybe you’re running it a bit hotter than it needs for this specific filament, maybe go down 5°C or 10°C. It seems when it slows down, more can ooze than it intends to.

It took some time to find the culprit.

It’s under:

Filament settings -> Cooling -> Cooling thresholds -> Slow down if layer print time is below: # - and - Min print speed: #

I am running a bit hot, yes, 215, and the extruder is bowden feed. It does tend to ooze a bit like all bowdens do, that’s why i have to get my speeds and accelerations on point, because the “dynamic” speed/extrusion settings never provide good results for this printer and i don’t know how to account for the oozing on speed changes.

I’d love to upgrade to a direct extruder, i’m currently using e3d v6 hot end. Do you have any suggestions?

Yes. Get something like the TBG S or TBG Lite. These things are tiny, light, have a massive gear reduction (~1:11), which trades unnecessary speed (E is always running really slow even if you print really fast) for strength, and they have huge dual gears driving the filament. With that you can extrude TPU as if it was PLA.

If you can’t find a fitting mount, I made one for the TBG Lite. PM me with some address where I can send you an STL if you are interested.

Eh, sadly can’t help too much with that. Used to have an Ender 5, but got an Artillery X2 gifted (aye…), and since then have been using that due to the combination of direct and the larger print bed (even though I conceptually don’t like bedslingers due to the large footprint they have). And I had the Ender 5 too briefly to dial it in much.

Does it always happen at the same height? Could be Z axis binding. What kind of printer do you have?

It’s a prusa-style printer, no make or model, i put it together from parts laying around! Edit: Z axis is fine, i regulary print tall objects and there’s no wobble, but thanks!

Please stop stealing the Twitter logo.

You need to dial up the linear advance just a hair to fix the bulging corners.

And you do look like your over-extruding by a hair as well.

Print a solid 20mm cube, 1 perimeter, 0% infill, 0 top layers.

It will print out a cube you can measure the wall thickness with a dial caliper.

The thickness should exactly match your extrusion width setting. If it does not, adjust your extrusion multiplier be how much your measurement is out.

Does it line up with the bottom of the z? If so - is it doing solid infill layers for the top few layers?

It’s dynamic speed related settings in prusa slicer. I’m fighting with that silcer for so long that sometimes i overlook some of the settings :(

For me that looks like slight overextrusion of the top layers. The first few layers are also slightly squished out. The Calibration Cube is a very extreme example. Before you start adjusting I’d print something more natural and if you don’t like that you can go through this: https://teachingtechyt.github.io/calibration.html

First layer is printed with 0,8mm and half as fast as the others, then the second layer i believe is regular width but still half the speed, that’s why it’s a bit squished down there.

I was mainly worried about the top, as i didn’t set anything speed or extrusion related for anything apart from the first two layers mentioned.

Otherwise, prints are okay, but i like to print a calibration cube every now and again just to check for possible maintainance required.

The correct answer for this is linear advance needs tuning. Google how to do that.

Other than that, getting a direct drive extruder like the TBG Lite will help a lot as well.

Does this imply too high or too low of a linear advance value?